Shrinking Chip Bag

We can’t get our hands on enough stuff to shrink. Faced with the problem of creating tiny chip bags, we turned to Steve. “I don’t […]

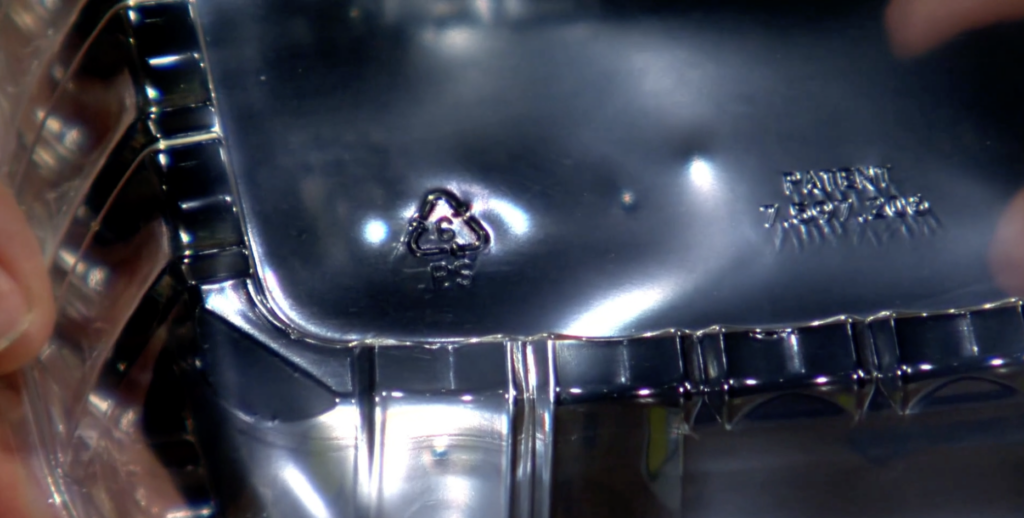

Shrinkies are a fun and creative way to repurpose plastic that might otherwise end up in a landfill. You can create awesome keepsakes using most clear containers from restaurants and delis. Simply look for a “6” inside the recycling arrows on the bottom of the container. By using a shrinky, the plastic will shrink to a third of its original size, while becoming 9 times thicker.

Find a clean piece of recyclable #6 plastic (polystyrene).

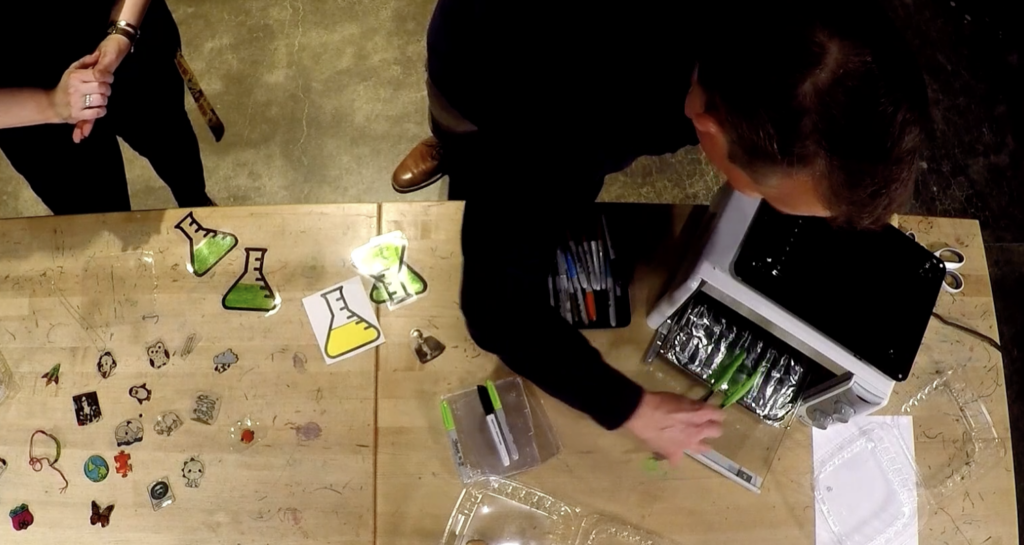

Cut the excess plastic away and make a flat sheet, you can use both the top and the bottom.

Use your imagination and create a masterpiece on the flat sheet using permanent markers.

Pre-heat your oven to 350 degrees and place a rack in the lowest position.

Cover a cookie sheet with aluminum foil or create your own tray out of aluminum foil by bending up the sides – the thinner surface allows for more direct heat and faster shrinking.

Put your shrinky in the tray onto of a piece of parchment paper and use tongs or an oven mitt to place it on the bottom rack of the pre-heated oven.

Allow your shrinky to cook for 1 -3 ½ minutes depending on the size. When in the oven, your art will begin to curl like crazy, but it will soon start to flatten itself out. Keep an eye on it and use the tongs or oven mitts to remove the tray.

After pulling out your shrinky, make sure to place it on a flat surface. It will still be pliable for about the first 10 seconds.

Polystyrene is a type of plastic, also known as #6 recycled plastic. It’s often used to make those clear boxes you see in restaurants or grocery stores for carrying food. When you heat this plastic in the oven, it starts to shrink and curl up, almost like it’s going to stick to itself, but then it flattens out again.

When we heat polystyrene, the tiny parts that make it up, called chains, go back to a jumbled-up shape. These chains have a special way of remembering this jumbled shape, even though they were stretched out and frozen in a different shape when they were first made. This is different from most things, which either get soft or melt when heated, or break down if they get really hot. Polystyrene shrinks a lot when heated, but it doesn’t lose any of its stuff (mass). It gets smaller in size, but thicker, to make up for it.

Shrinky Dinks® are a fun craft toy that was created in 1973 by Betty Morris from Brookfield, Wisconsin. They were super popular in the 1980s. Shrinky Dinks® are made of thin, bendy sheets of a plastic called polystyrene. Before you heat them, you can color and cut these sheets into different shapes. When you bake them in the oven, they shrink to about one-third of their original size and get nine times thicker and harder, but they still keep the colors and designs you added.

You can buy Shrinky Dinks® at stores like JoAnn™ Fabrics and Michaels©. But, you can also make something similar at home using clear plastic containers (made of recycled plastic #6) like the ones used for sandwiches and salads. You can cut, smooth, and decorate these containers just like Shrinky Dinks®. The cool thing about these toys is how the polystyrene is made into thin sheets.

The way all solid things, including plastics, turn out depends on how they are made. The temperature, the way they are made, and how fast they are made are all important. Making something out of raw materials (like turning plastic into a shape) is called processing. Most plastic sheets are made by a process called extrusion.

In extrusion, the raw material is pushed through a hot tube by a spinning screw. The material melts and is squeezed through a shape-maker, called a die, to get its final form. The raw polystyrene is heated to 190°C and pushed through a die. The film that comes out is still hot, around 100°C, so it’s soft and stretchy. To make the film stretch in two directions, it’s pulled in a way that’s different from how it came out of the machine. Then, it’s rolled up by cool rollers to make it harden quickly.